A decade ago, 3D printers were for educational purposes only, used by scholars or engineers. Today, students can have their own machines.

September 14, 2022

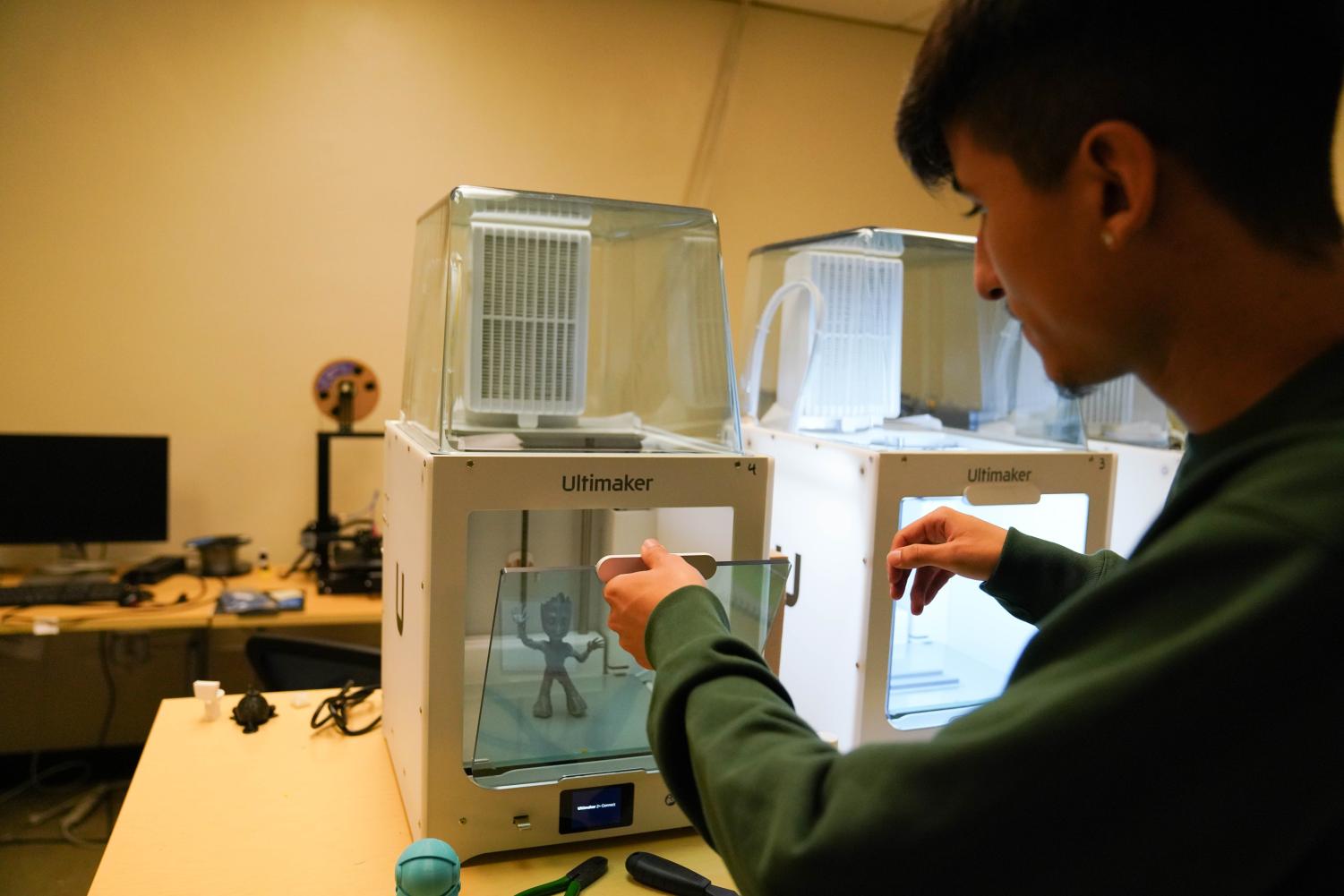

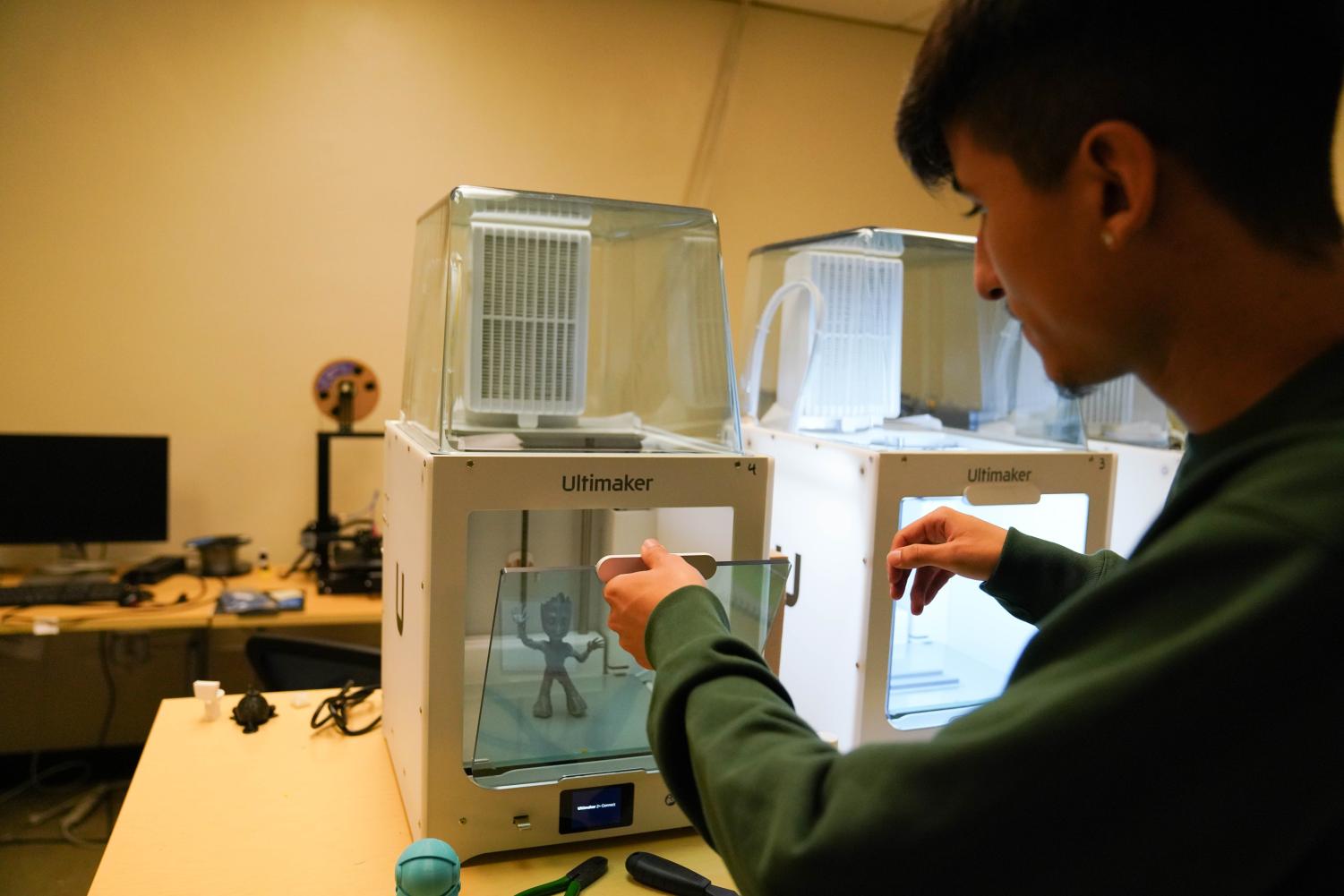

MakerSpace—SF State library’s digital media studio—opened seven years ago and has become a hub for students to access 3D printers. While the resource would have been a rare commodity years ago, engineering and design students often own their own printers now.

The space reopened this semester, after closing over two years ago during the beginning of the COVID-19 pandemic. Similarly, the Rapid Prototyping Lab, a student-run 3D printing lab that facilitates engineering students, aims to relaunch this year as well.

Professor Silvan Linn runs the Industrial Design program on campus and teaches prototyping, manufacturing and other design principle classes in the School of Design.

Linn began using a 3D printer in college when they were more expensive and costed around $50,000.

According to Linn, costly 3D printers can now produce multiple materials simultaneously and can use transparent materials, such as rubber and plastic.

He said that 3D printer usage can range from fulfilling a job, to making figurines to creating household appliances.

“I use it at home just for random things,” Linn said. “If I need a little hook to hang a mirror for shaving or a mirror in the shower or something, it’s okay, and I’ll print something for that.”

Printers with different materials can run for around $200 now.

“Lots of people have them, more and more of my students are now telling me, ‘I’ve already got a 3D printer at home, can I just put my project at home instead of on the school’s printers?’” Linn said.

Third-year Industrial Design major Jared Oelschlaegel is taking advantage of a cheaper, more accessible printer this year.

Oelschlaegel owns a Creality CR-10 model printer, an inexpensive printer with a one-foot, one-square footprint space. The device allowed him to continue 3D printing during the pandemic.

“When the pandemic hit, I saved some money and bought a 3D printer,” Oelschlaegel said. “I just kept playing with the programs they use in class and got pretty good at them.”

With his own printer, Oleschlaegel was able make 3D models for money.

Oelschlaegel does freelance for friends, family, commissions small props for events and prints designs that people send him. One of his recent projects was a 3D printed photo that you hold to the light to see the image in black and white.

While students often own their own 3D printers, SF State’s on-campus tools have become a useful resource to students interested in creating physical prototypes.

Senior Mechanical Engineering major Jason Ludwig has worked at the Engineering Stockroom in Thornton Hall for the last two semesters. He oversees the 3D printers in the lab and helps students that don’t know how to use the machines.

Senior engineering students can use the room to create prototypes for their projects. If the project is not school related, students must pay for the material.

“Previously, not all teachers required prototypes but more often, they are nowadays and one of the ways that they can create prototypes is by 3D printing them,” Ludwig said.

Ludwig’s most recent 3D project was a carburetor spacer, which he made from PCB board to work on his car.

Most people would opt to buy a part like that online or at a car parts store, but since Ludwig had access to a 3D printer, he decided to use what was available to him.

“Instead, I got the old one and changed it where needed, and because I made it out of plastic, that was more heat resistant,” Ludwig said. “I was able to create a new version of the part without buying a new one.”

The opportunity to fabricate specific size parts for a custom fit application or an entire piece for some assembly, are things that drive Ludwig to create with 3D printers.

He said the printers are a resource that enables prototypes to become more than a concept. While design prototyping is important, he said that a 3D prototype can accomplish more.

“That’s not to say that work isn’t hard,” Ludwig said. “But it doesn’t prove anything until it becomes physical in some form. So it’s a real first step towards making something physical that you can then show off to investors or anyone else.”

Engineering students like Ludwig and design students like Oelschlaegel agree that 3D printing opens doors for more success.

“3D printing gives you a lot of room to grow and develop your design skills,” Ludwig said. “3D printing, in particular, is the most accessible type of prototyping to get into, where you don’t have to know much. You can make mistakes.”